A Comprehensive Guide to 3D Printing – Unlocking Endless Possibilities

Introduction to 3D Printing

In the realm of creation and innovation, 3D printing has emerged as a game-changer, offering unparalleled versatility and efficiency across various sectors. From rapid prototyping to customized manufacturing, 3D printing presents a cost-effective and highly adaptable method of production. However, for those new to this technology, the world of 3D printing can be somewhat intimidating, involving more than just owning a printer and filament.

This comprehensive guide aims to empower individuals and businesses eager to explore the exciting world of 3D printing by providing essential insights into the supplies, materials, considerations, and costs associated with this revolutionary technology. By the end of this guide, readers will possess a thorough understanding of what it takes to harness the full potential of 3D printing, unlocking infinite creative possibilities.

Understanding the Basics

Essential 3D Printer Supplies

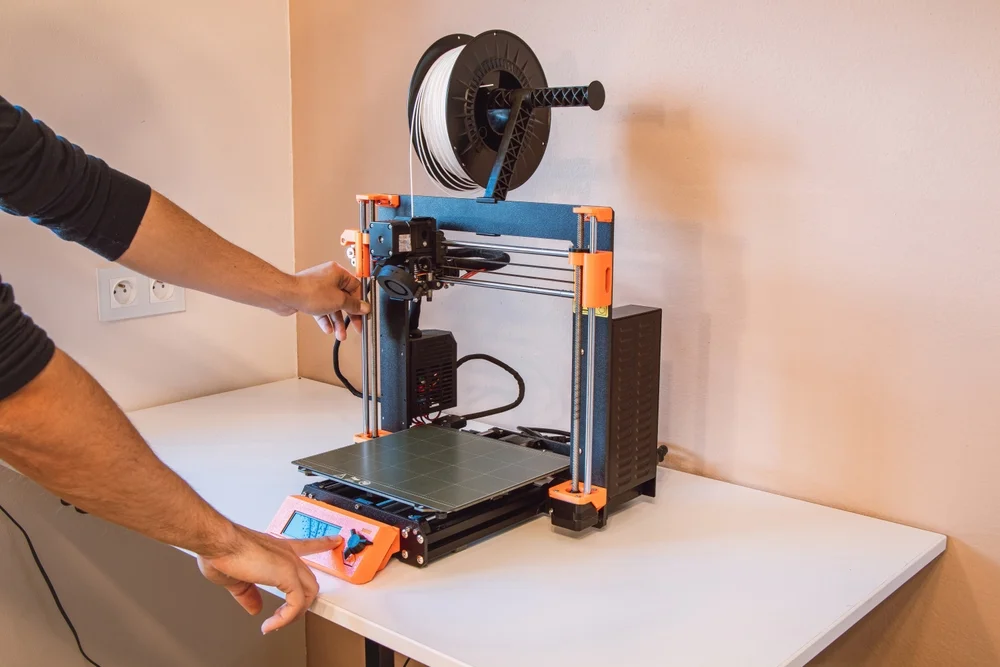

The first step on your 3D printing journey is to acquire a suitable 3D printer. The market offers an extensive array of options, each employing distinct technologies and catering to specific needs. Here’s a breakdown of the most common types:

Stereolithography (SLA)

SLA printers utilize ultraviolet light to cure and solidify liquid resin, layer by layer, resulting in highly detailed prints with smooth surfaces. This technology is renowned for its accuracy and is commonly employed for creating precise prototypes and small-scale models.

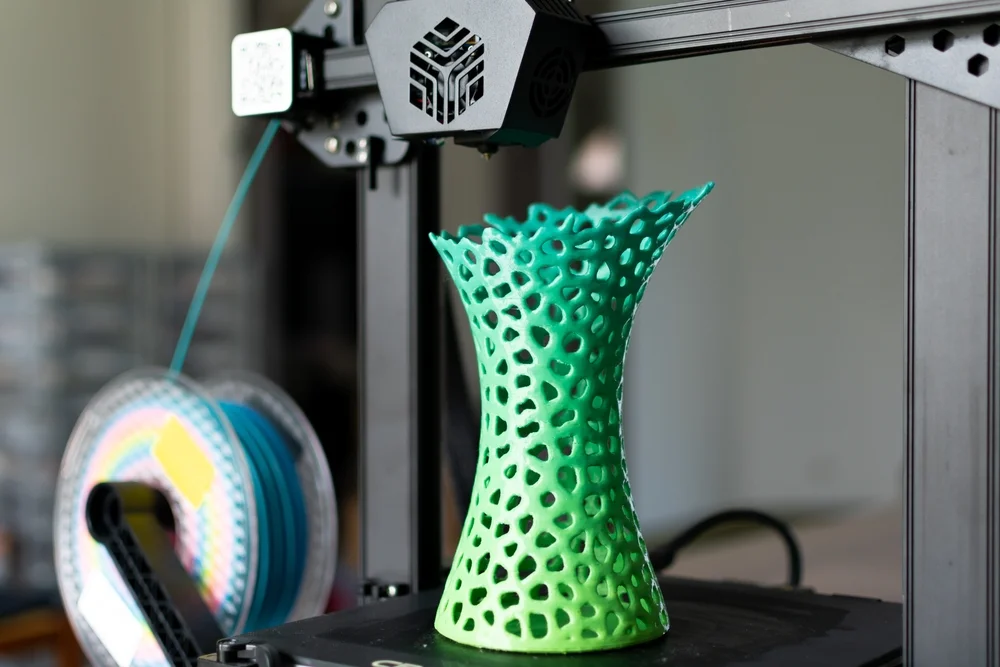

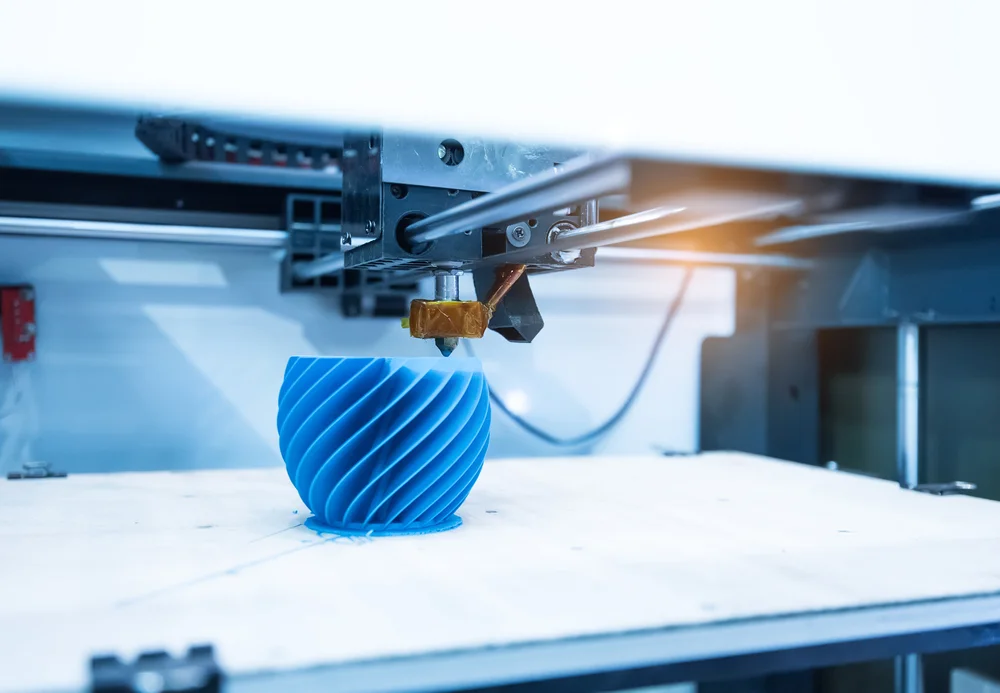

Fused Deposition Modelling (FDM)

FDM printers work by extruding melted plastic filament through a heated nozzle, building objects layer upon layer. They are widely popular due to their affordability, user-friendliness, and ability to print with a diverse range of materials. FDM printers are versatile, making them ideal for both hobbyists and professionals.

Digital Light Processing (DLP)

DLP printers utilize digital light projectors to cure liquid resin, similar to SLA printers. They offer faster printing speeds and higher resolutions, making them the preferred choice for producing intricate models and prototypes with exceptional detail.

Selective Laser Sintering (SLS)

SLS printers employ a laser to fuse powdered materials, such as nylon or polyamide, layer by layer. This technology enables the creation of complex geometries and functional prototypes with outstanding durability.

Direct Metal Laser Sintering (DMLS)

DMLS printers utilize a high-powered laser to fuse metal powders, resulting in solid metal objects with remarkable precision. This process is ideal for producing highly durable metal parts for aerospace, industrial, and medical applications.

Essential Accessories and Maintenance

In addition to selecting the right type of 3D printer, there are several essential supplies and accessories that will ensure a seamless and successful printing experience:

- Storage Containers: Proper storage is critical to maintaining the quality of your printing materials. Airtight containers help prevent moisture absorption, keeping filaments and resins fresh and ensuring optimal print quality.

- Adhesives: Adhesives are vital for securing your prints to the build plate, preventing any unwanted movement or detachment during the printing process. Common options include glue sticks, hairspray, and specialized 3D printing bed adhesives.

- Build Plates: Build plates provide a flat, stable surface for your prints to adhere to. Different materials are available, such as glass, aluminum, or heated build plates, each offering unique advantages in terms of adhesion and surface finish.

- Ventilation Equipment: 3D printing can generate fumes and odors, depending on the materials used. Proper ventilation is essential for maintaining a safe printing environment. Consider investing in an air purifier or setting up a dedicated ventilation system.

- Precision Tools: Calipers and micrometers are essential for measuring the accuracy and precision of your prints, ensuring they meet the desired specifications and dimensional accuracy.

- Maintenance Toolset: 3D printers require regular maintenance and occasional repairs. A basic toolset, including screwdrivers, wrenches, and cleaning tools, is crucial for keeping your printer in optimal condition.

Exploring the World of Printing Materials

Unlocking the Possibilities

The choice of printing material is pivotal in determining the success of your 3D printing projects. Each material possesses unique characteristics, influencing the strength, flexibility, durability, and aesthetic of your printed objects. Here, we provide a comprehensive overview of the most commonly used printing materials and their applications:

Plastics

Plastics are the most widely used printing materials due to their affordability, ease of use, and versatility.

Polylactic Acid (PLA)

PLA is a biodegradable plastic derived from renewable resources such as corn starch or sugar cane. It is user-friendly, offering good dimensional accuracy and a smooth finish. PLA is suitable for a broad range of applications, from prototypes to consumer products, thanks to its ease of printing and eco-friendly nature.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a durable and impact-resistant plastic commonly used in consumer goods, toys, and electronic enclosures. It offers high strength and heat resistance, making it ideal for functional prototypes and end-use parts. ABS can also be post-processed through sanding, painting, or gluing, providing a smooth and professional finish.

Powders

Powder-based materials are used in technologies like SLS and binder jetting, offering unique advantages in terms of strength and flexibility.

Polyamide (Nylon)

Nylon powder is known for its durability, flexibility, and impact resistance. It is a popular choice for printing functional prototypes, tools, and end-use parts in industries such as automotive and aerospace, thanks to its excellent mechanical properties.

Alumide

Alumide is a composite material that combines aluminum and nylon powders, offering the best of both worlds. It provides a metallic appearance, high strength, and stiffness, making it suitable for structural components and durable prototypes.

Resins

Resins are used in SLA and DLP printers, providing exceptional detail and smooth surfaces.

Standard Resins

Standard resins are versatile and suitable for a wide range of applications. They offer high accuracy and are commonly used for small-scale models, miniatures, and detailed prototypes. These resins are generally affordable and easy to work with, making them a popular choice for hobbyists and professionals alike.

Specialty Resins

Specialty resins are designed for specific applications, offering unique properties such as flexibility, high-temperature resistance, or clear transparency. For example, flexible resins are ideal for printing rubber-like parts, while high-temperature resins can withstand extreme conditions.

Metals

Metal 3D printing, facilitated by technologies like DMLS, enables the creation of highly durable and precise metal parts for various industries.

Stainless Steel

Stainless steel offers excellent corrosion resistance and strength, making it suitable for industrial and engineering applications. It is commonly used for printing functional prototypes, tools, and end-use parts that require high strength and durability.

Aluminum

Aluminum is lightweight, strong, and widely used in aerospace, automotive, and consumer electronics industries. It is often chosen for its combination of strength, low weight, and good thermal conductivity.

Titanium

Titanium provides an exceptional strength-to-weight ratio and superior corrosion resistance, making it ideal for medical implants, aerospace components, and high-performance automotive parts.

Composite Materials

Composite materials are created by combining two or more materials, enhancing specific properties and opening up a world of possibilities.

Carbon Fiber

Carbon fiber-reinforced plastics offer exceptional strength and stiffness, making them ideal for structural components in aerospace, automotive, and sports equipment industries. The addition of carbon fiber significantly improves the mechanical properties of the base plastic, resulting in lightweight yet extremely strong parts.

Graphene

Graphene-enhanced materials provide improved thermal, electrical, and mechanical properties. This revolutionary material enables advanced electronics and high-performance applications, thanks to its superior conductivity and strength.

Considerations and Costs of 3D Printing

While 3D printing offers significant cost-saving opportunities, particularly in prototyping and small-batch production, it is essential to consider the various expenses involved. Here’s a comprehensive overview of the factors contributing to the overall cost of 3D printing:

Printer Cost

The initial investment in a 3D printer can vary significantly depending on the technology, brand, features, and intended use. Consumer-grade FDM printers, for instance, can range from a few hundred to a few thousand dollars, offering a cost-effective entry point for beginners and hobbyists. On the other hand, industrial-grade printers, such as SLS or DMLS machines, can cost substantially more, often reaching tens of thousands or even hundreds of thousands of dollars.

Printing Materials

The choice of printing material has a direct impact on the cost of your projects. Plastic filaments, such as PLA and ABS, are generally affordable and accessible, with prices typically ranging from $20 to $50 per kilogram. However, specialty materials can significantly increase the overall cost. For example, metal powders used in DMLS printing can be extremely expensive, often costing several hundred dollars per kilogram. Similarly, carbon fiber-infused filaments or specialty resins with advanced properties may also carry a higher price tag.

Accessories and Maintenance

The cost of essential accessories, such as build plates, adhesives, precision tools, and storage containers, should be factored into your budget. Additionally, 3D printers require regular maintenance and occasional repairs, which may include replacing nozzles, print beds, or other components over time. These ongoing maintenance and replacement costs need to be considered for a seamless printing experience.

Post-Processing

Depending on the printing technology and material used, post-processing may be necessary to achieve the desired finish. This can include support removal, sanding, painting, or additional surface treatments. For example, SLA and DLP prints often require post-curing under UV light to fully harden the resin, while FDM prints may need to be sanded and painted for a smooth finish. These post-processing steps can add to the overall cost and time required for each project.

Power Consumption

The electricity consumption of 3D printers varies depending on their size, technology, and usage. Industrial-grade printers, for instance, consume significantly more power than desktop FDM printers. Additionally, operating multiple printers simultaneously or running printers for extended periods can result in higher electricity costs. Therefore, it is essential to consider the ongoing cost of electricity, especially for larger-scale operations.

Labor

While 3D printing can automate certain aspects of production, skilled labor is still necessary for design, setup, monitoring, and post-processing. The level of expertise required will depend on the complexity of the project. For instance, designing intricate 3D models may demand the skills of a professional designer or engineer. These labor costs can vary widely and should be carefully considered, especially when outsourcing these services.

Overhead Costs

If you’re running a 3D printing business or service, don’t forget to account for overhead costs such as rent, utilities, marketing, and administrative expenses. These costs can significantly impact the overall profitability of your 3D printing endeavors and should be carefully planned and managed.

Unlocking the Full Potential

In conclusion, 3D printing opens up a realm of limitless possibilities, empowering individuals and businesses to bring their ideas to life. However, to truly harness this potential, it is crucial to approach 3D printing with a comprehensive understanding of the supplies, materials, and considerations involved.

By investing in the right equipment, selecting suitable printing materials, and carefully planning for associated costs, you can unlock doors to incredible creativity, innovation, and efficient manufacturing. Whether you’re a hobbyist exploring new possibilities or an established business seeking to revolutionize your production processes, 3D printing has the potential to transform the way you create, enabling you to turn your visions into reality.

As you embark on this exciting journey, stay curious, stay informed, and continuously seek ways to maximize the benefits that this versatile technology offers. With the right knowledge, tools, and mindset, the possibilities are, quite literally, endless.

Final Thoughts

We hope this comprehensive guide has provided you with a thorough understanding of the world of 3D printing. As you delve deeper into this exciting field, remember to stay adaptable and embrace the constant advancements and innovations that define this dynamic industry.

Happy printing!

Appendix: Quick Tips for Successful 3D Printing

- Calibrate your printer regularly: Calibration ensures accurate and consistent results. Most 3D printers offer automatic or manual calibration options to maintain optimal performance.

- Experiment with different materials: Each material has unique properties, so don’t be afraid to explore the wide range of plastics, resins, and powders available.

- Pay attention to safety: 3D printing involves high temperatures and potentially hazardous materials. Always follow safety guidelines and ensure proper ventilation.

- Join online communities: Engage with other enthusiasts and professionals to stay updated on the latest trends, seek advice, and share your creations.

- Post-processing makes a difference: Don’t underestimate the power of post-processing techniques to elevate the quality and finish of your prints.

- Invest in quality filaments: Quality filaments ensure consistent results and reduce the risk of printing failures. Reputable brands often provide more reliable and consistent results.

- Keep a maintenance log: Regular maintenance is key to the longevity of your printer. Keep a log of maintenance tasks and create a schedule to stay on top of it.

- Utilize slicing software features: Slicing software allows you to fine-tune various printing settings. Experiment with these settings to optimize your prints.

- Consider recycling failed prints: Failed prints can be recycled and reused, reducing waste and providing an eco-friendly approach to learning.

- Have fun: Above all, enjoy the process of creating and exploring the endless possibilities that 3D printing offers!

Glossary of 3D Printing Terms

- 3D Printing: A process of creating three-dimensional objects by depositing or solidifying material layer by layer, following a digital model.

- Additive Manufacturing: A manufacturing process that builds objects by adding material layer by layer, as opposed to subtractive manufacturing, which removes material.

- FDM (Fused Deposition Modelling): A type of 3D printing technology that extrudes melted plastic filament through a heated nozzle, building objects layer by layer.

- SLA (Stereolithography): A 3D printing process that uses ultraviolet light to cure and solidify liquid resin, resulting in highly detailed objects.

- DLP (Digital Light Processing): Similar to SLA, DLP uses digital light projectors to cure liquid resin, offering faster printing speeds and higher resolutions.

- SLS (Selective Laser Sintering): A process that uses a laser to fuse powdered materials, layer by layer, creating durable and complex objects.

- DMLS (Direct Metal Laser Sintering): A technology that uses a high-powered laser to fuse metal powders, creating solid metal objects with high precision.

- Filament: A thermoplastic material in a strand or thread form, used as feedstock for FDM 3D printers.

- Resin: A liquid material that is cured and solidified using ultraviolet light or digital light projection, used in SLA and DLP printers.

- Build Plate: A flat, stable surface on which objects are printed, providing a foundation for the printed object.

- Calibration: The process of adjusting and fine-tuning a 3D printer’s settings and hardware to ensure accurate and consistent printing results.

- Slicing Software: Software that takes a 3D model and slices it into thin layers, generating the necessary toolpaths and instructions for the 3D printer to follow.

- Post-Processing: The steps performed after the initial printing process to finish and refine the printed object, including support removal, sanding, painting, or additional treatments.

- Overhang: A feature of a 3D printed object where a layer of material is printed without support from the layer below, creating a ‘floating’ effect.

- Infill: The internal structure of a 3D printed object, which can be adjusted to save material and improve print speed while maintaining structural integrity.

- Support Structure: Temporary material used to support overhangs and intricate details during printing, which is removed in the post-processing stage.

- Raft: A base layer of material printed underneath an object to provide additional support and improve adhesion to the build plate.

- Bed Adhesion: The process or technique used to ensure the printed object adheres properly to the build plate, preventing warping or detachment.

- Warping: A common issue in 3D printing where the corners or edges of an object lift or curl up due to uneven cooling or poor bed adhesion.

- Layer Height: The thickness of each layer deposited or solidified during the printing process, affecting the overall print quality and speed.

- Resolution: The level of detail and precision achieved in a 3D printed object, influenced by factors such as layer height, nozzle size, and printing technology.

- CAD (Computer-Aided Design): Software used to create and modify 3D models, allowing designers to create digital prototypes and detailed designs.

- STL (StereoLithography) File: A common file format used in 3D printing, which describes the surface geometry of a 3D model, allowing it to be sliced and printed.

References

- “3D Printing Technologies: The Complete Guide.” MatterHackers, https://www.matterhackers.com/articles/3d-printing-technologies.

- “3D Printing Materials: The Ultimate Guide.” All3DP, https://all3dp.com/1/3d-printing-materials/.

- “The 11 Best 3D Printing Materials, Explained.” Digital Trends, https://www.digitaltrends.com/cool-tech/best-3d-printing-materials/.

- “3D Printing Filaments: The Ultimate Guide.” MatterHackers, https://www.matterhackers.com/articles/3d-printing-filaments.

- “The Pros and Cons of 3D Printing.” Formlabs, https://formlabs.com/blog/pros-and-cons-3d-printing/.

About the Author

Inkhive Printers is a passionate 3D printing enthusiast and expert with over 15 years of experience in the industry. They have witnessed the transformative power of this technology first-hand and are dedicated to helping others unlock its full potential. Through their work, they aim to empower individuals and businesses to embrace the exciting world of 3D printing and turn their creative visions into tangible realities.

Copyright and Disclaimer

This guide is protected under copyright laws and is intended for personal use only. While every effort has been made to ensure the accuracy of the information provided, the author and publisher do not assume any responsibility for errors, omissions, or contrary interpretations. The information presented is not intended as professional advice, and users should exercise their judgment and seek expert advice when necessary.

Any references to specific products, services, or brands are for informational purposes only and do not constitute an endorsement or recommendation. The author and publisher disclaim any responsibility for any damages or losses incurred through the use or misuse of this guide.

Reproduction or distribution of this guide without the express written permission of the author is strictly prohibited.

Feel free to reach out with any questions or feedback, and happy printing!

Copyright © UKBrands4Less 2024

Enjoy your journey into the exciting world of 3D printing!